STRETCH WRAPPING MACHINES

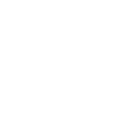

Cosmetic products, skin care products and other types of speciality products are often stretch film wrapped and labelled. The use of this distinct, luxury packaging style is increasing worldwide. The Stretch Wrappers are designed to wrap with polyethylene stretch film and to label bar soaps and other solid products of all shapes.

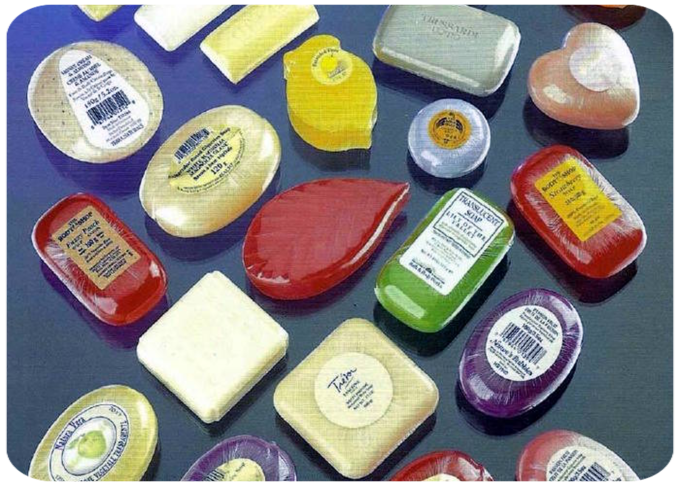

Technical specifications:

- Rotary indexing product infeed table with twelve easy to remove rubber pockets contoured for each individual product shape.

- To feed the products automatically info the indexing infeed table an optional Automatic Transfer system is available.

- Automatic labeler for roll-fed self-adhesive labels.

- Ten minute fast and easy product changeover.

- Two-step film pre-stretching system for optimal tight wrap quality.

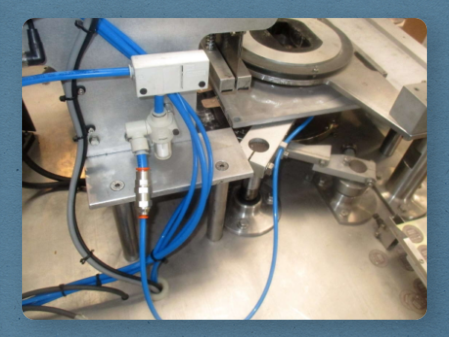

- All machine motions ore cam operated and continuously monitored and controlled by a PLC.

- Adjustable Frequency Drive motor.

- Rugged machine frame with stainless steel side covers.

- Electronically interlocked PVC safety guards.

- Continuous motion product discharge conveyor.

- Large excess film collecting container.

- Centralised lubrication system.

Operating Sequence

- Manual Product Infeed

- Automatic Product Infeed - Optional System. The products can be fed automatically into the rubber pockets with the Automatic Transfer group.

- A vacuum suction cup arm moves the product info the wrapping head assembly.

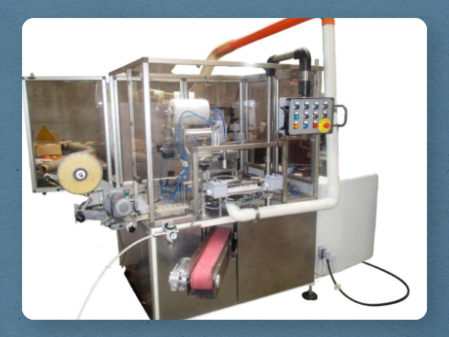

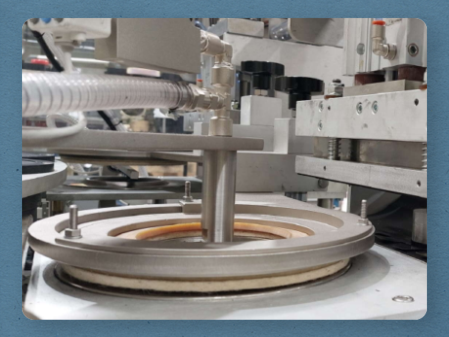

- The film is pre-stretched as the product together with the film is lowered into the wrapping head assembly.

- An iris type closing mechanism stretches the film very tightly around the product.

- A hot knife cuts off the excess film and seals it. Two mechanical fingers remove and discard the film through a discharge tube into an excess film collecting container.

- A cam driven arm places a roll fed self-adhesive label on top of each product.

- The stretched wrapped and labelled products are placed onto a continuous motion discharge conveyor.

MODEL AVAILABLE | SPEED (s.p.m.) | PRODUCT LENGTH | PRODUCT WIDTH | PRODUCT HEIGHT |

CE-15 | 15 | from 40 mm to 110 mm | from 25 mm to 80 mm | from 10 mm to 45 mm |

CE-50 | 50 | from 40 mm to 110 mm | from 25 mm to 80 mm | from 10 mm to 45 mm |

CE-75 | 70 | from 40 mm to 110 mm | from 25 mm to 80 mm | from 10 mm to 45 mm |