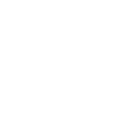

IMA BFB 3703 BUNDLING MACHINE

Reconditioned IMA BFB 3703 was designed to group products and overwrap them in single, double, or triple rows arranged on one layer. The bundling process takes place in line with the product outfeed, while remaining outside the actual wrapping section. Products are conveyed by side belts, preventing shifting or instability even at high infeed speeds. A motorized star wheel rotates incoming items onto their side, while the final pack formation is completed through a powered collation system.

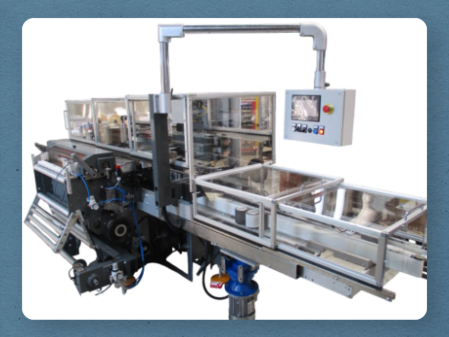

Format changes are quick and straightforward thanks to the use of pre-assembled and pre-set units, minimizing machine downtime and improving overall efficiency.

Technical specifications:

- In-line infeed belt conveyor with the outlet

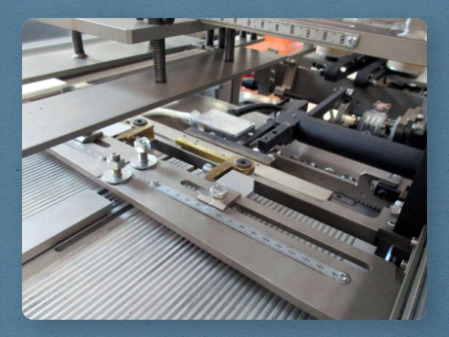

- Mechanical stacking mechanism for bundles of 1, 2 or 3 layers

- Layer separators

- Bundle pusher with special profiled motion for high speed operation

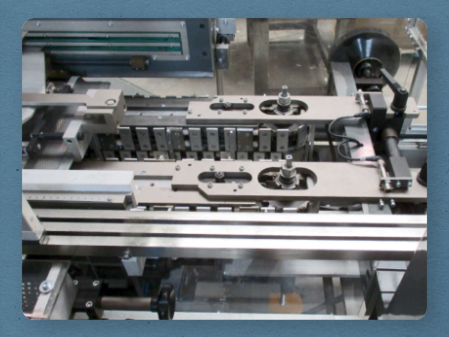

- Sealing station for the transversal seal

- Side Teflon belt conveyors for sealing with independent motion

- Operator guards with safety interlocks

- One set of change parts included

- Brand New Electrical Panel

Maximum Speed:

- Up to 100 strokes per minute (depending on machine configuration).

Product Sizes:

- Min: 60 x 25 x 60 mm

- Max: 260 x 130 x 220 mm

Optional:

- Infeed belt conveyor at 90° with the outlet

- Customized size group

- Print registration device for printed wrapping material