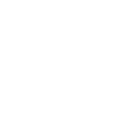

PLEAT WRAPPING MACHINES

Pleat wrapping machines are engineered to create twenty-four folds while applying labels to solid products such as adhesive tapes, PVC tapes, bearings, round cheeses, and various round or oval-shaped goods. Premium fragrance soaps and luxury hotel soaps are often packaged using pleat wrapping. This elegant and distinctive packaging style enhances product presentation and is ideal for round and oval items with a side band.

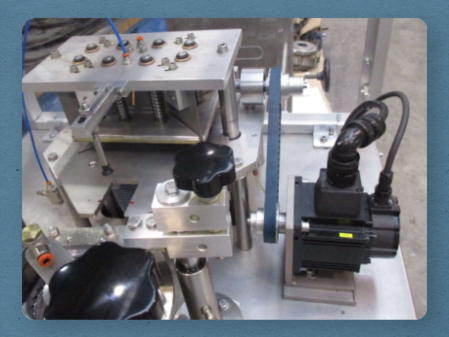

We supply different models of reconditioned Guerzé pleat wrappers.

Technical specifications:

- Intermittent motion infeed conveyor.

- Continuous motion discharge conveyor.

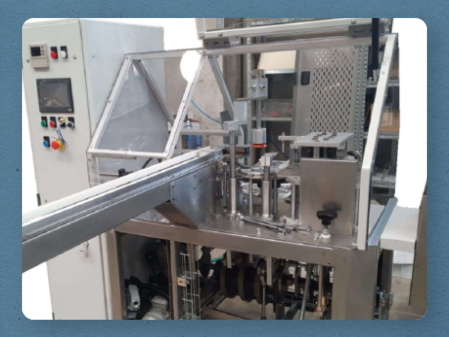

- Automatic labeler for roII-fed self-adhesive Iabels.

- Paper cuffing group with size change without extra size parts.

- Fifteen minute fast and easy product changeover with few size parts, the adjustment are electronically made.

- All machine motions are cam operated and continuously monitored and controlled by a PCL.

- Rugged machine frame with stainless steel side covers.

- Adjustable Frequency Drive motors.

- Electronically interlocked PVC safely guards.

- Centralized lubrication system.

Operating Sequence

- The products are fed onto an intermittent motion infeed conveyor.

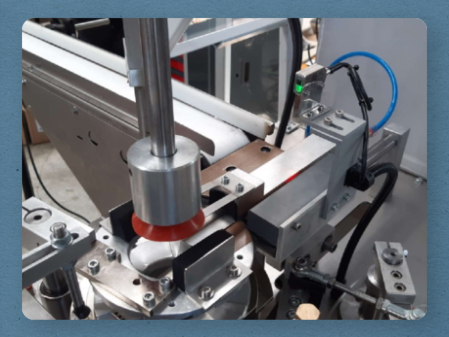

- A cam driven vacuum suction cup arm transfers the product from the infeed conveyor into the roil fed wrapping material which was cut into an octagonal shape. The product together with its wrapping material is lowered into a pleating head assembly group, where twenty four pleats are formed. The excess wrapping material Is cui off and discharged with a vacuum system into a net bag.

- The folded pleats are securely maintained by a mechanically controlled iris system as the pleating head with the product inside moves to the labelling station, where the label is applied.

- The pleat wrapped and labelled products are discharged into a continuous motion discharge conveyor.

MODEL AVAILABLE | SPEED (s.p.m.) | PRODUCT Ø | PRODUCT HEIGHT |

PL-40 | 40 | from 40 mm to 80 mm | from 12 mm to 50 mm |

PL-50 | 50 | from 40 mm to 80 mm | from 12 mm to 50 mm |

PL-75 | 70 | from 40 mm to 80 mm | from 12 mm to 50 mm |