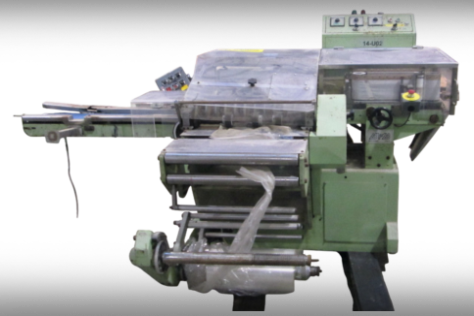

RECONDITIONING PROCESS

Our reconditioning process of used packaging machines is carried out through a highly scrupulous and structured process, designed to restore used packaging machines to the highest standards of performance and reliability. Each used packaging machine undergoes a complete overhaul, following a series of carefully defined steps that ensure quality, efficiency, and long-term operation.

The reconditioning process strictly follows the 10 points listed below:

- Complete disassembly of the used packaging machine and in-depth inspection of all mechanical components

- Technical evaluation of the used machine to identify worn, damaged, or obsolete parts

- Replacement of all worn-out components to restore the original performance of the packaging machine

- Manufacturing of missing or unavailable parts

- Thorough cleaning, surface treatment, and repainting of the machine

- Mechanical overhaul and reassembly of the packaging machines

- Installing a new electrical control panel with PLC, Touch Screen and other parts as agreed with the Customer

- Functional testing and fine tuning of the reassembled packaging machine

- Final testing of the machine using the customer’s final product

- Quality control procedures to ensure reliable, efficient, and long-lasting packaging machine

We supply refurbished machines with 12 months of Guarantee