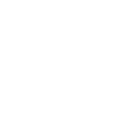

BFB 3728 CASE PACKER

The BFB 3728 automatic case packer is designed for loading individual cartons or multipacks into cardboard cases. It fulfills modern industrial requirements in terms of compact design, quick format change, and dependable performance. The BFB 3728 case packer control is managed by a PLC system, supported by a display that assists the operator during use and changeover procedures. Case sealing can be performed using self-adhesive tape, hot-melt glue, or cold glue systems.

Format (size group) adjustments can be completed without tools, with settings guided by digital position indicators. A case magazine ensures convenient loading. Cases are positively opened by a dual-arm mechanism with suction cups, ensuring accurate squaring during product insertion—even when using lower-quality cardboard. The cases are then securely transferred to the closing section.

Technical specifications:

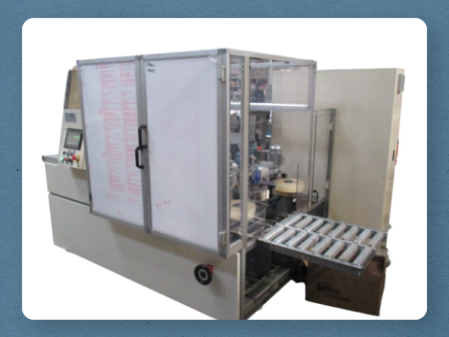

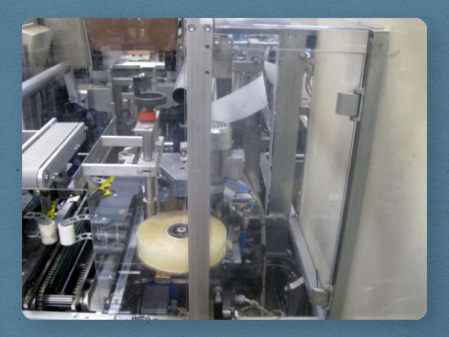

- In-line infeed system

- Staking Mechanism for formation of bundles

- Pusher (Case Filler) with movable trough

- Final folding

- Case Taping section with adhesive tape

- Interlocked Safety Covers

- Brand New Electrical Panel

CASE ERECTOR

- Case Magazine

- Automatic opening and partial folding of Cases from magazine

- Automatic positioning of Cases on feeding trough

Maximum Speed:

- Up to 15 cartons per minute (depending on machine configuration).

Carton Sizes:

- Length: from 200 to 550 mm.

- Width: from 120 to 350 mm.

- Thickness: from 120 to 350 mm.

Optional:

- Hot melt system for carton closure