SOAP WRAPPING MACHINES

A soap wrapping machine is designed to automatically enclose individual soap bars in packaging material (such as paper, film, or laminates). Its main functions are to protect the soap bars, ensure hygiene, and prepare it for retail.

The main purpose of a soap wrapping machine is to improve both speed and uniformity in packaging. Contemporary systems are frequently designed to operate as part of an integrated production line, working in coordination with soap stamper or soap cutter.

Soap Wrappers comes in multiple setups to accommodate a range of soap shapes like rectangular, oval, and circular bars, as well as different dimensions and types of wrapping materials.

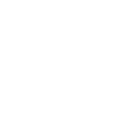

ACMA 711

The ACMA 711 Soap Wrapping Machine is an intermittent motion soap wrapper suitable to wrap both rectangular and oval bars with or without side band at a speed up to 180 wraps per minute. The paper feeding is from heat sealing reel. The wrapping style is double-point end fold.

The fully reconditioned second-hand wrapping machine is supplied complete with:

- main electrical motor with speed variator

- in-line infeed with rotary suction-cup group

- 2 infeed reel holders for outer paper

- 2 infeed reel holders for inner stiffener

- New electrical and electronic panel

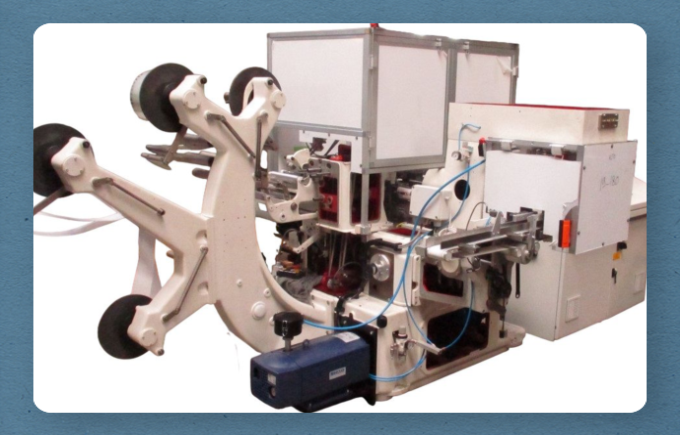

ACMA 791

The ACMA 791 Soap Wrapping Machine is suitable to wrap both rectangular and oval bars with or without side band at a speed up to 300 wraps per minute and over. The paper feeding is from heat sealing reel. The wrapping style is double-point end fold.

The fully reconditioned second-hand wrapping machine is supplied complete with:

- Dual lane right angle infeed with two reciprocating suction-cups

- main electrical motor with speed variator

- 2 + 2 infeed reel holders for inner and outer paper. It is possible to prearrange two stand-by reels (for outer paper and stiffener) while the machine is in production.

- New electrical and electronic panel

ACMA 771

The ACMA 771 High Speed Soap Wrapper is an In-Line Soap Wrapper based on full continuous operation: the soap bar, once taken by the suction-cups, never stops while it is wrapped. This assures smooth operations of positioning, wrapping, folding and sealing at any speeds up to 500 wraps per minute.

The production speed depends on the specification and quality of the wrapping material and product to be wrapped.

The ACMA 771 Soap Wrapping Machine is suitable to wrap both rectangular, oval, banded and bandless soap bars, using inner stiffener from continuous reel and heat-sealing outer wrap from continuous reel. The outer wrap can be heat sealing paper or BOPP (Bi-Oriented Polypropylene).

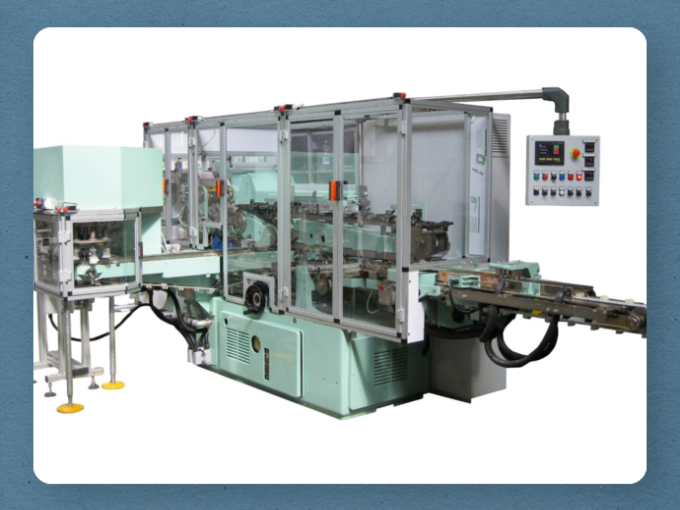

CARLE & MONTANARI P22

The C&M P22 Soap Wrapping Machine is a continuous motion soap wrapper suitable to wrap both rectangular and oval bars with or without side band at a speed up to 200 wraps per minute. The paper feeding is from heat sealing reel. The wrapping style is double-point end fold.

The fully reconditioned second-hand wrapping machine is supplied complete with:

- main electrical motor with speed variator

- vacuum pump with independent motor to keep the stiffener and outer paper when they meet the soap bar

- 2 infeed reel holders for inner and outer paper

- New electrical and electronic panel

OTHER MODELS

We have available other models of used/reconditioned Soap Wrapping Machines for sale, like:

- ACMA 761 for toilet soap bars

- ACMA 741 for toilet soap bars

- ACMA 731 for hotel soap bars

- ACMA 781 for laundry soap bars

- C&M P23 for laundry soap bars

- Other models of soap wrapping machines coming soon